Laser System Manager (LSM) for ULTRA Series

The Laser System Manager (LSM) is the control software for ULTRA laser systems. It provides an advanced user interface with a high degree of functionality and control that allows users to efficiently operate the laser system, manage design files, and apply laser material processing parameters.

All laser system and software functions are easily accessible through the LSM interface including:

Design File Import, Printing, and Management

The LSM supports importing of industry standard files including DXF, PDF, and G-Code. In addition to importing, design files can be transferred to the laser system via a printer driver workflow available for Window’s and macOS operating systems. Design files are converted to control files in the LSM. Control files consist of design file information plus laser system control settings. Control files are displayed in visual grid or list view and can easily be searched by image or by file name.

Application of Laser Processing Settings

The laser processing settings that are applied to a control file for laser processing a material or application are accessed through the LSM. Settings available include: raster, vector, speed, power, PPI, image density, dithering, acceleration, cutting order, processing direction, segment reduction, gas flow rate, SuperSpeed™ control, and rotary axis control.

Settings can be automatically generated and applied to a control file by using pre-defined parameters available through the Intelligent Materials Database or customized by the user.

Intelligent Materials Database

A powerful and unique database that automatically generates optimized laser processing parameters for a wide variety of materials (including different types and thickness) based on the laser power ratings and wavelengths configured on the laser system. For more details see Intelligent Materials Database Innovation.

Customize

Custom laser settings for a specific material or thickness not listed in the Intelligent Materials Database can be created by applying settings. Users can also adjust the pre-defined settings generated by the Intelligent Materials Database to create custom settings. Customized settings created by the user can be saved as recipes and applied to any control file.

In addition to these operation settings, the LSM offers additional advanced features to achieve optimal material processing results:

Kerf Compensation

A user adjustable control that compensates for material width removed during laser cutting to achieve desired dimensions without changing the design file. It maintains true arc and circle geometry if present in the design. This feature can save setup time by eliminating the need to adjust the design file geometry in the original design software.

Drill Feature

The Drill Feature allows users to drill holes with a user-defined duty cycle and number of pulses at specific (X,Y) locations in the processing area. This allows users to create much smaller and more uniform holes in thin materials than would be possible by creating circles using a vector process. This feature can also increase productivity since it focuses on a single point for a hole instead of multiple points required for a circle.

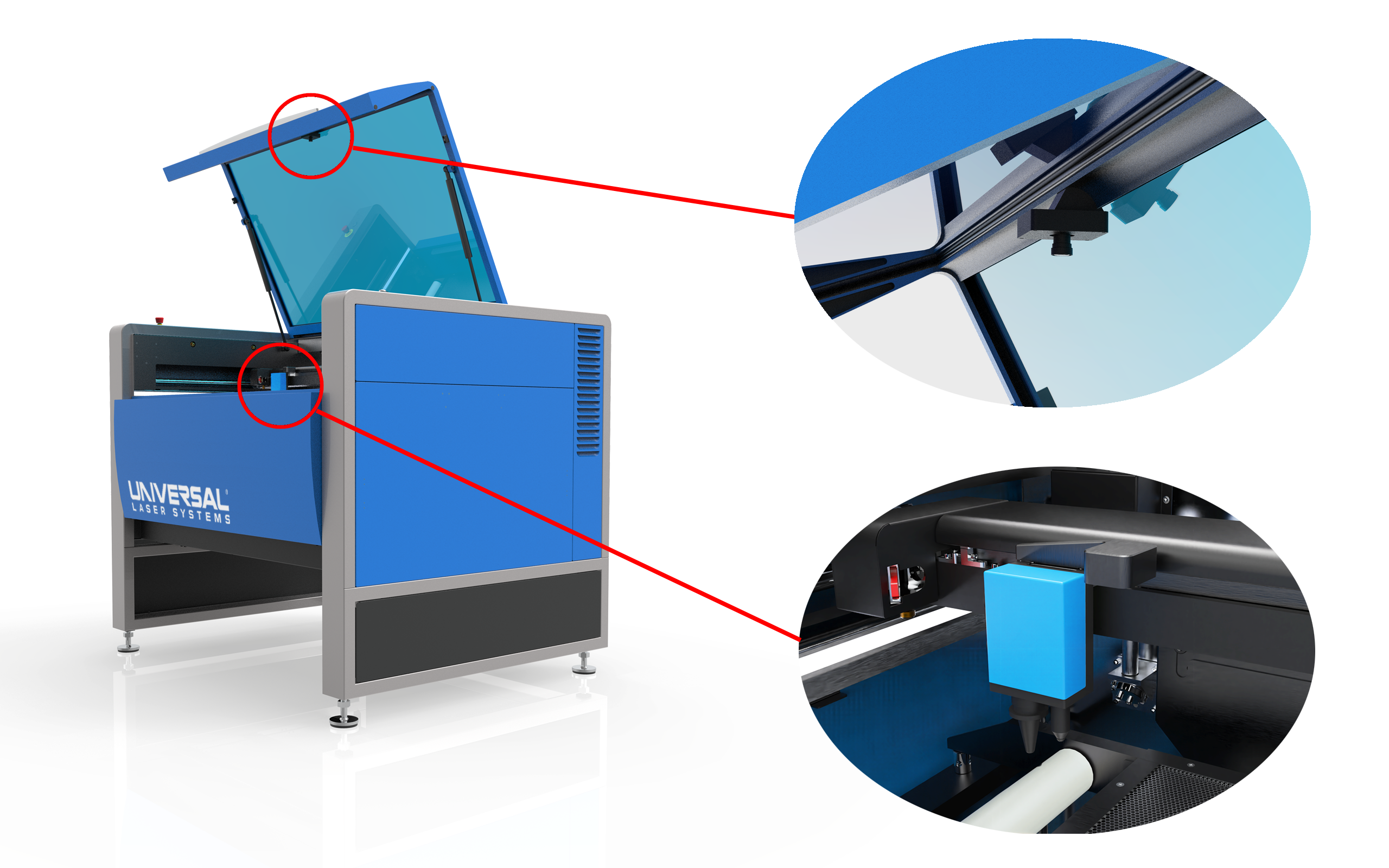

Camera Control for Vision and Positioning

For ULTRA laser systems with an installed camera or cameras, the LSM displays camera images (vision) and contains all controls for camera related functions including locating registration marks and positioning control files on materials. A door mounted camera that is positioned from the material when the door is open is used to provide an overall view of the entire multi-function material support structure and materials placed on it. A carriage mounted camera that can be repositioned directly over material placed on the multi-function material support structure provides a high resolution close-up view. Additionally, the carriage camera is used for high-precision location of registration marks.

Precision Material Independent Autofocus Control

The LSM contains controls to set the autofocus probe positioning and activation for multiple points of focus to enable users to achieve high quality and consistent repeatable results. The focus operations are performed automatically and in the sequence and locations defined by the user.

System Control with Automation Interface

The Automation Interface is an addressable device that can receive input signals and provide output signals. This enables the laser system to control external devices and allows external devices to initiate laser system functions. The Automation Interface is controlled by the LSM. For more information see Automation Interface Innovation.

System Configuration and Calibration Settings

Configuration settings including Units (inches or millimeters), Laser Diode Control, X-Y Homing Before Processing, and Autofocus (on/off) are available in the LSM. Calibration settings can be changed using a set of wizards and dialogs. Calibration functions include: Y-Axis, Autofocus, Alignment, Ruler Offsets, Lens, Carriage Camera, Door Camera, Rotary, and SuperSpeed™. Calibration is performed at the factory prior to shipment of the system and during installation. Once initial calibration is performed, further calibration is not needed. However, calibration may be required after updating system software, replacing components, or as part of a diagnostic procedure.

Wired and Wireless Network Management

ULTRA systems can access either a wired or wireless network. This LSM function allows selection of network and device naming. Connection to a network is optional but enables Remote Diagnostics and Remote Operation from browser compatible devices on the same network.

User Access and Administration

User names, logins, and privileges are all administered through the LSM. For logins, users can be required to log in locally or given remote access. Administrators have the ability to set user privileges to include or exclude: modifying control files, modifying users, operating the laser system, viewing all control files, and configuring the laser system.

Help and Diagnostics

The Help & Diagnostics Page provides information on the laser system’s state, provides access to Remote Diagnostics, and enables the user to update the LSM software.

Contact us to learn more about specific capabilities of the Laser System Manager (LSM).